Case studies: Automated dairy product manufacturing equipment

Customer

Customer

A major company in the United Arab Emirates specialised in marketing dairy products.

Project

Project

The company wanted to implement a production and bottling plant for fresh milk, fruit or chocolate-flavoured milkshakes, and liquid yoghurts, such as leben.

The customer wanted a supplier with sector experience capable of planning, equipping, and implementing a complete installation

The customer wanted a supplier with sector experience capable of planning, equipping, and implementing a complete installation

Why INOXPA?

Why INOXPA?

The customer wanted a supplier with sector experience capable of planning, equipping, and implementing a complete installation.

INOXPA had previously worked on a project for a customer from the same group. The project involved supplying a valve manifold. This meant that the company already had references and recommendations about our work and the quality of our equipment.

INOXPA solution

INOXPA solution

The proposal was comprehensive and presented to the customer as a solution comprised of different equipment for automatically preparing and bottling a range of dairy products, also including a heat treatment and cooling system.

Installation characteristics

Installation characteristics

- An automated mini-plant for preparing dairy products with a capacity of 500L/h, with a 48kW heat treatment and 56kW cooler unit.

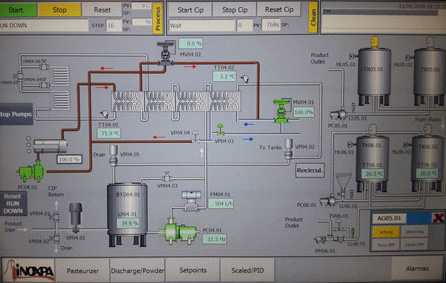

- A PLC control system that records set and actual parameters.

- A unit to receive the milk and cool it down from 35 ⁰C to 4 ⁰C

- 2 pasteurised milk vats with a capacity of 500L

- 2 pasteurised milk fermentation tanks for yoghurt with a capacity of 250L

- 2 powder blenders with a capacity of 500L

Special features

Special features

Combining the equipment into one installation provides a comprehensive solution for preparing different dairy products.

The fully automated mini-plant has PID controlled and recorded heat treatment and cooling. This provides complete traceability for the process.

Production processes are easy to change to adapt to different types of milk and dairy products.

Request information

Automated dairy product manufacturing equipment