Bioreactors: maximum precision and efficiency in every process

30/09/2024

SystemsAn industrial bioreactor is a skid designed to provide a controlled environment where micro-organisms, animal or plant cells, or biomass can grow, multiply and produce specific biological products. Given they can facilitate large scale biological processes efficiently and in a controlled manner, bioreactors are essential for a range of industries, including the pharmaceutical, food, chemicals, and veterinary medicine industries.

A fermenter is a specific type of bioreactor used to perform fermentation processes, when micro-organisms convert substrates into products, such as transforming milk into yoghurt.

Ensuring a good level of sterilisation in a bioreactor is very important to avoid potential contamination risks. The process can involve using steam directly, or by heat applied from a heating chamber around the tank. An industrial sterilisation process to inactivate micro-organisms and bacteria normally takes about 30 minutes at a temperature of around 130ºC. The tank needs to be aseptic and pressurisable up to 3 bar in both cases, complying with the PED pressure equipment directive.

INOXPA BIOREACTOR: stirred-tank bioreactor

Stirred-tank bioreactors are widely used in the industry as agitators can constantly mix the ingredients inside the tank.

- Applications: Production of chemical products, fermentation of micro-organism for pharmaceutical and food products.

- Advantages: Can provide controlled agitation, can be scaled up.

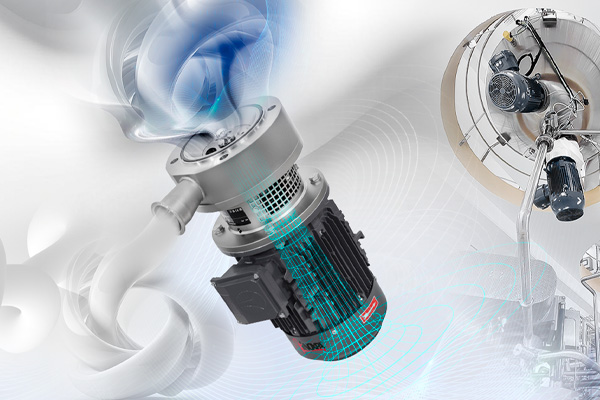

With extensive expertise in agitation and mixing, INOXPA's division has mastered the selection of optimal skids, ensuring homogeneous dispersion. INOXPA’s fermenters are provided with CXC agitator model, as it uses a mechanical seal to ensure the sealing of the tank. Radial or Rushton turbines are used to homogenise the product properly, as they are excellent at dispersing gases in liquids. This type of blade ensures that the oxygen injected by the diffuser is mixed with the product uniformly.

Bioreactor components

A bioreactor creates a controlled environment, in which such factors as temperature, pH, oxygen and nutrients are maintained at optimal levels. The precise control of these parameters maximizes the growth and development of microorganisms or cells and the efficiency in the production of the desired products. Agitation is a key aspect to ensure the best possible homogenisation of gases and nutrients. INOXPA employs their extensive experience with agitation and mixing components to assemble the most efficient skid for these types of processes.

The main components

- Growth chamber: It is a stainless steel aseptic tank where the micro-organisms or cells grow and develop.

- Agitation system: Uniform mixing of nutrients and gases is carried out using Rushton turbine, which is excellent at dispersing gases in liquids.

- Temperature control: The optimal temperature is maintained using heating or cooling systems.

- pH control: pH measurement allows to assess the current status of the process.

- Gas diffuser: The oxygen needed for aerobic organisms is provided by means of aeration or by injecting oxygen.

- Turbidity: A turbidity indicator (in NTUs) is used to monitor the growth of microorganisms.

- Feeding and harvesting systems: They inlet and outlet are used to provide nutrients and remove products and waste in a controlled, aseptic environment to prevent contamination.

- Gas control: Gas concentration is monitored inside the tank.

Bioreactor fields of use

Bioreactors are versatile and essential skids for a wide range of industries and uses, which include the pharmaceutical, food, chemical and environmental sectors. Their capacity to create a controlled environment for growing and producing micro-organisms and cells makes them a vital component for industrial sustainability and innovation.

Pharmaceutical industry

Bioreactors are essential for biotech medicinal products, such as monoclonal antibodies, vaccines, insulin, vitamins and amino acids.

Chemical industry

Bioreactors enable chemical product synthesis and industrial enzyme production. Uses include the production of biopolymers, biosurfactants, bioplastics and other organic chemical products.

Food industry

They are used for producing food and drinks via fermentation processes and growth of beneficial micro-organisms. Uses include the production of enzymes, probiotics, yoghurt, cheese, beer, wine and other fermented products.

Other industries where bioreactors are used include environmental and waste water treatment, biofuel production, fertiliser production, etc.

With years of experience in the food and pharmaceutical sectors, INOXPA provides customized hygienic equipment to meet our clients' specific needs. INOXPA fermenters are no exception, as they are designed to ensure proper cleaning and sterilisation via CIP (Cleaning in Place) and SIP (Sterilisation in Place), complying with GMP and FDA directives. They are an ideal choice for biotechnology production and development as they can be integrated into modern control systems and comply with the most stringent directives.