ME-6100 RE: new recirculation tank bottom mixer

20/11/2024

MixingINOXPA introduce the new recirculation tank bottom mixer.

This new family of mixers ME-6100 RE further expands such an important range for our sector as we cover the mixing needs for a wide range of applications.

The recirculation tank bottom mixer is a very hygienic solution for the processes of dispersion, emulsion, homogenisation and disintegration of solids in the food, cosmetic, pharmaceutical and fine chemicals industries.

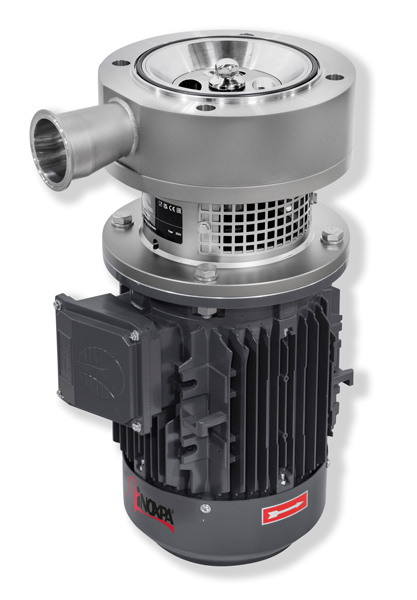

In contrast to other models, the ME-6100 RE high shear mixer has a head specially designed to recirculate the product, ensuring more homogenisation throughout the tank.

Furthermore, thanks to its pumping capacity, no displacement pump is required for emptying or moving the product from the tank. The mixer itself fulfils this function, avoiding the need to install a positive displacement discharge pump. This characteristic is a significant benefit in terms of competitiveness, given that the price of a transfer pump impacts the skid’s total price.

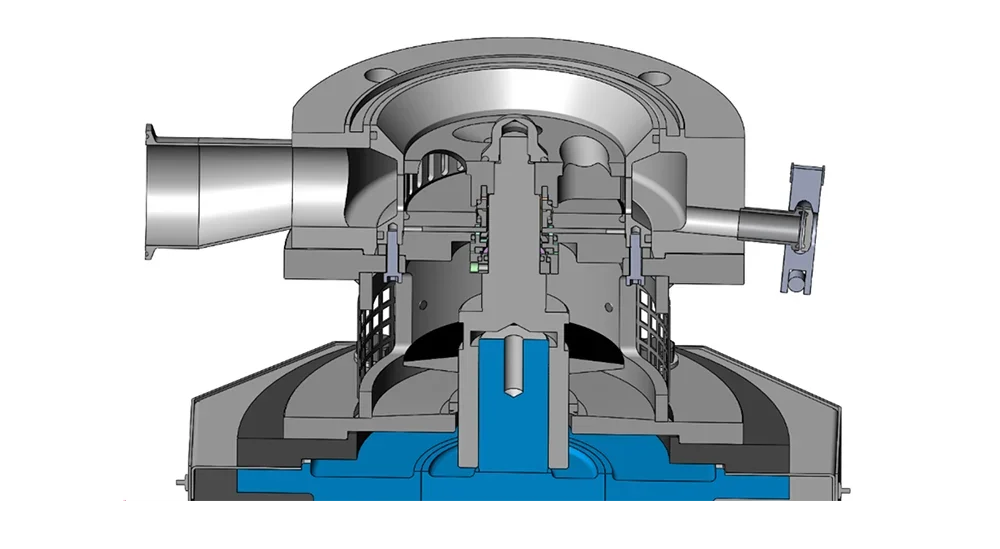

The ME-6100 RE has a more closed rotor-stator unit that gets completely flooded when the product passes through the head.

This ensures that all the recirculated product is exposed to high shear, improving the mixing result, with particles being reduced to sizes under 100 microns.

Main features:

- Single mechanical seal, accessible from inside the tank.

- Different easily interchangeable stator models.

- Easy cleaning and sterilisation using CIP/SIP processes.

- Optional double mechanical seal.

- Fully drainable via the eccentric outlet connection.

Using a recirculation tank bottom mixer allows for a simpler additional agitation required by the process.

For example, a recirculation mixer with an anchor agitator can be used when manufacturing emulsions, instead of choosing a more complex option such as a counter-rotating agitator.

Furthermore, this model performs the process quicker than a standard bottom mixer.

The new ME-6100 RE recirculation tank bottom mixer by INOXPA provides a versatile and efficient solution for a wide range of applications. It is an excellent choice for optimising production processes, increasing competitiveness and ensuring high quality results.