Equipment for vaccine manufacturing

01/12/2020

SystemsGiven the current SARS-CoV-2 virus pandemic, some pharmaceutical companies are racing against time to obtain an effective and reliable vaccine. A huge amount of resources has been invested in developing one as soon as possible.

Many companies are currently going through the advanced stages of development, but once the investigation phase has ended and health organisations have given their approval, the pharmaceutical industry will then face their next challenge: large-scale vaccine manufacturing. This will involve pharmaceutical companies having to make significant investments in equipment to produce the vaccine.

As a manufacturer of equipment, plants and installations for the pharmaceutical industry, INOXPA can use our experience to offer these types of equipment, tailored to a customer’s individual requirements, with the following standard features:

- Tanks in AISI 316L with an internal Ra<0.5 finish.

- Jacketed and insulated tanks for heating and cooling.

- Certification under directive PED 2014/68/EU for operating at -1/+3 pressure and sterilisation at 130ºC for 30 min.

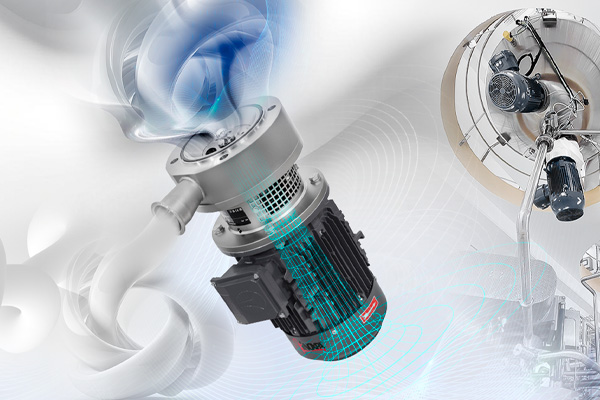

- Bottom magnetic drive agitator.

- Equipment prepared for in-place cleaning and sterilisation (CIP/SIP).

- Diaphragm valves.

- Control instrumentation: pressure sensor, temperature sensor, oxygen sensor, pH sensor, level sensor.

- Control panels, with PLC, HMI Siemens and an optional recorder.

- IQ/OQ validation protocols.

INOXPA hopes to help in the fight against this new virus that has permeated our lives.

Please contact us should you need any further information

https://www.inoxpa.com/company/contact